Modeling Glasses

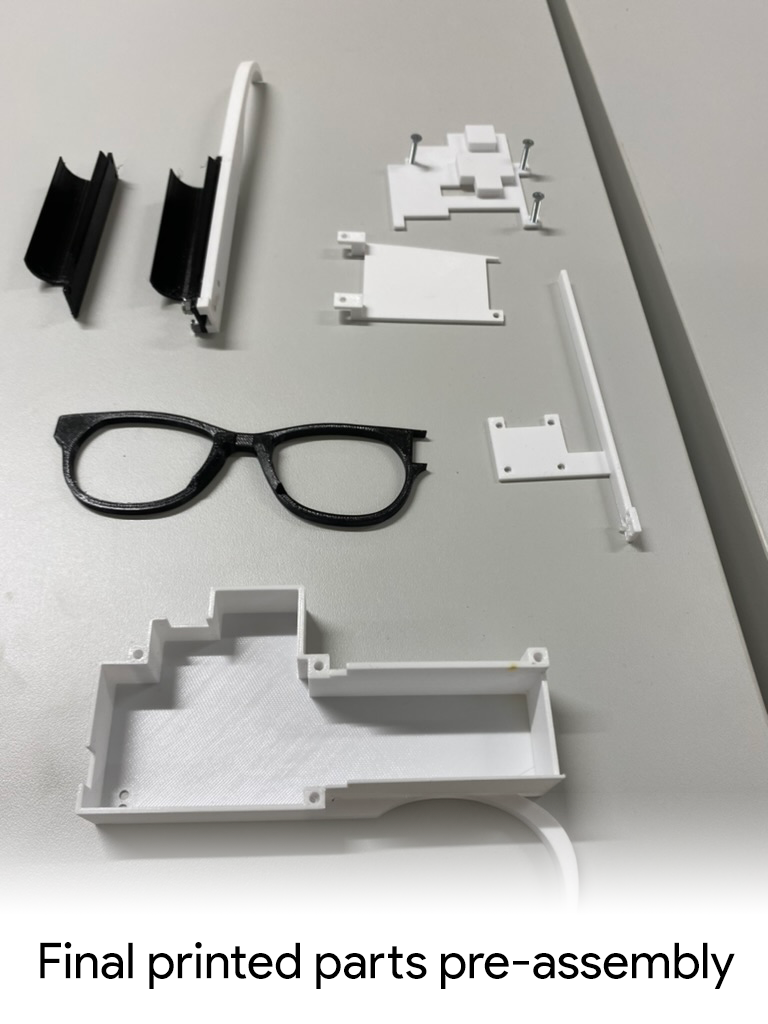

In order to build the frame of our glasses we first designed them using Fusion360 before ultimately uploading them to PrucaSlicer in order to print them on basic 3d printers using PETG or PLA (types of plastic that come at a very low cost).

To design custom glasses in 3d it is good to first find examples of already designed glasses on the internet or if you have any pair of glasses laying at home you can use those for an initial design.

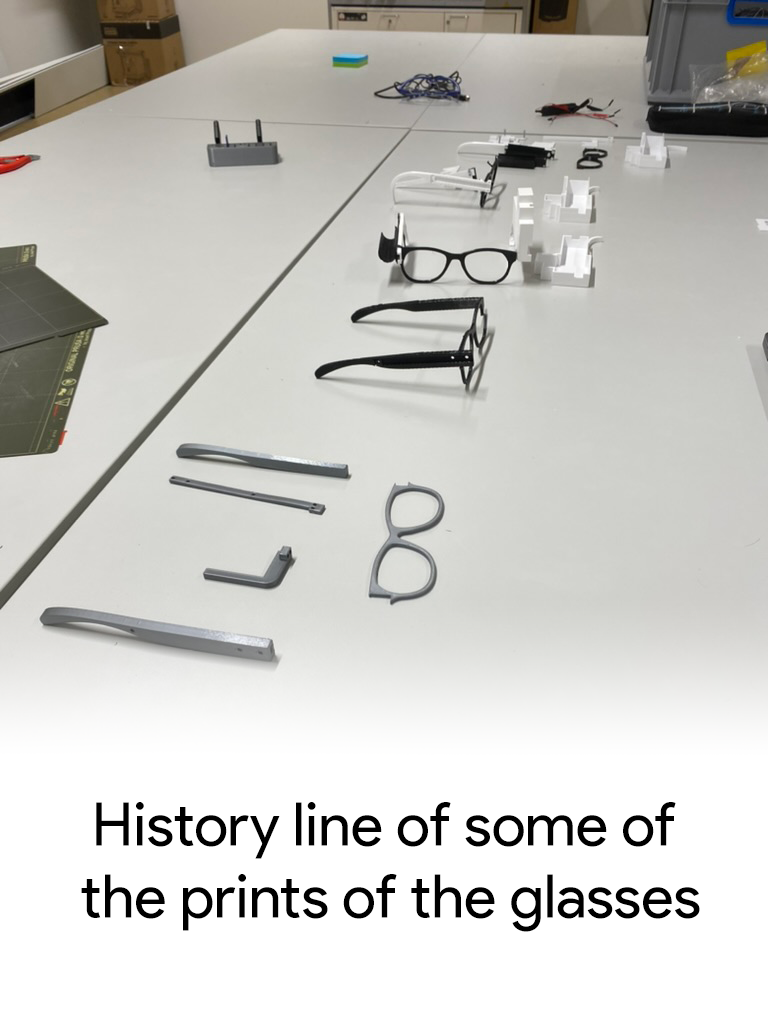

Once you’ve done that you will want to start adding features custom for your use into the design. In our case the main component of our glasses came from the transparent OLED display sitting at a little distance from our eyes. You can therefore see that in our first versions we already had a system to attach this feature to our glasses.

One print vs Multiple

One question that may arise will printing your first parts is should you print the glasses all together or in separate parts? (Difference seen in the two neighboring pictures.) The truth is it will depend a lot on how high a quality your available printer can print. In our experience, since we only had access to quite basic printers, printing in plastic using a precision of 0.2 mm. There was very little that pushed us towards a full body print.

What we did is we printed multiple smaller pieces that we would then screw or glue together. In doing so our prints were cleaner and overall had way more structural integrity.

Once we knew how we wanted to build the general design of our glasses we started working on the different components that were making it up more closely. Indeed, it is very important to always have an overall view of what your end design should look like and how each part improves the overall design. That is also why it is important to work in synergy with the other parts of your team in order to achieve a fluidity between components. You need to know how big the electronic circuits are going to be in order to print their encasing!

Our design

We’ll now dive a bit more into the specifics of our design:

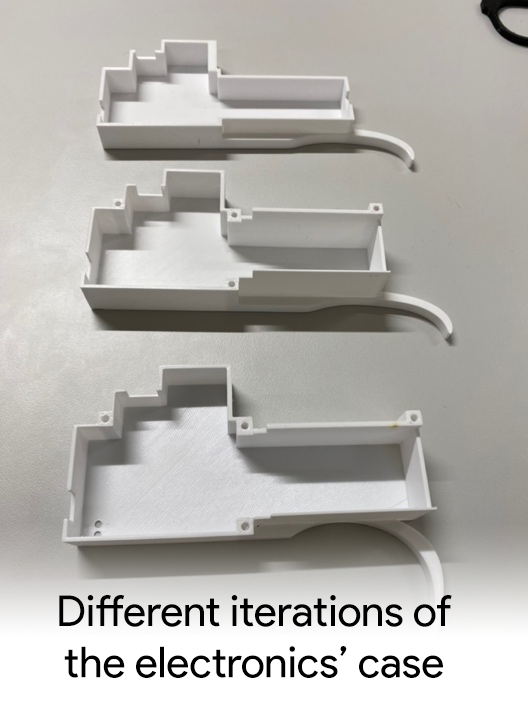

We knew quite early what the general size of our different electronics would be and so we had quite early an idea of the encasing we would attach to it. Barring of course the update where all electronics would be fitted into a customized PCB. And this helped us in the designing of our other parts.

Adjusting pieces

Every piece we printed multiple times, giving us time to adjust in order to make the design better keeping in the mind what we said about keeping an overall view of the glasses. As an example, the main piece of the glasses where the lenses usually are as well as the two “branches” going behind the ear were continuously developed for it to be as comfortable as possible. Trying to keep more area of surface with the nose and having a less pointy shape around the ears.

Some design flaws

This is where a few of the major problem about these glasses started to show up mainly:

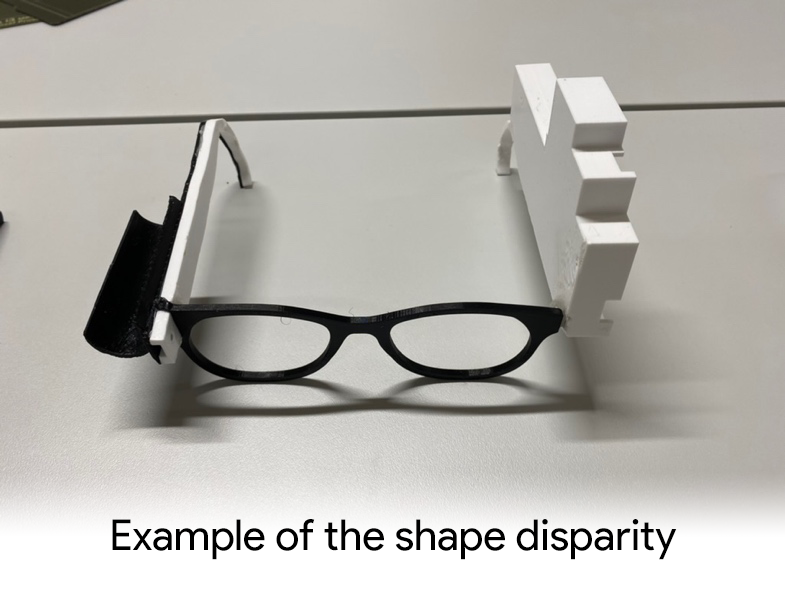

Weight distribution and how each person has a different head

Of course, the problem of weight distribution seems quite glaring: our components are simply not the same size. Therefore, we decided to put the battery and the screen on one side and the other major electronic components on the other. Making it at least somewhat of a more centered weight. In retrospect, it may have been better to split the Circuit board into two pieces in order to achieve a better balance overall.

The other major roadblock we encountered was how everyone’s head is simply so different. When glasses would be a perfect fit for one, they would be way too big for another and smaller for a third. Usual glasses don’t suffer from this setback as much simply because their weight is very balanced, and they are just lighter in general. This implies that they can get away with having relatively straight glass branches (needing only minimum support from the ears). This remained and still is a knock to the current design. To overcome this, we would have had to either making a more modular pair of glasses (Everyone can adjust them based on their needs) or simply focusing on reducing the overall weight of the glasses.

In conclusion, knowing this is only a proof a concept for a next generation of glasses. We have achieved just that. We have proved that such a concept is possible even at low cost however it would imply a careful rethink of components and adjusting some of the issues presented above.